Comprehensive Guide to Modern Metal Bending Systems

Introduction to Bending Machines

Metal bending is a core process in industrial fabrication, enabling flat sheets to be transformed into functional components. Achieving accurate bends is essential for product quality, structural stability, and efficient assembly. Various bending systems have evolved to meet modern manufacturing demands, each offering unique capabilities for different applications.

This article examines the diverse range of bending machines, their applications, and the advantages they provide to fabricators.

Why Accuracy Matters in Metal Bending

Precision in bending ensures that components fit correctly in assemblies and maintain their intended strength. Even minor deviations in bend angles or positions can compromise structural integrity, leading to part failures or assembly difficulties. Machines designed for controlled bending provide consistent results, improving reliability and reducing material waste.

Mechanical Bending Systems

Mechanical bending machines utilize levers, cams, or flywheel mechanisms to apply force to metal sheets. They are generally faster for simple bending tasks and cost-effective for smaller production runs. These machines are suitable for thin metal sheets but may struggle with thicker materials or complex bend profiles.

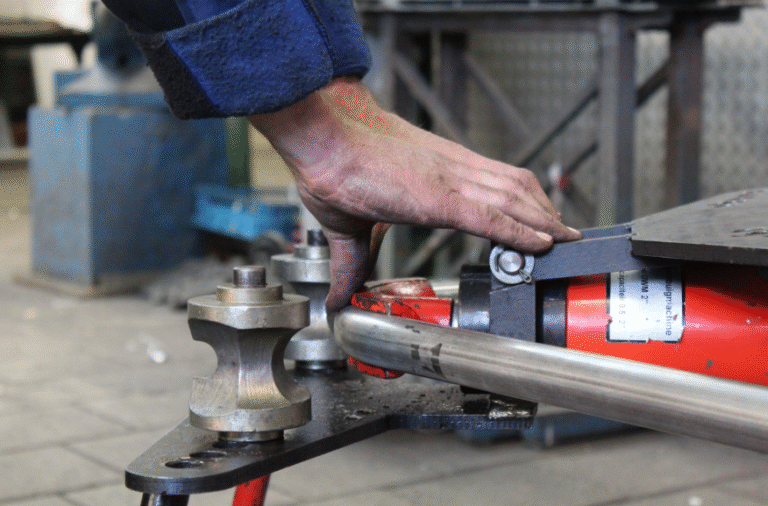

Hydraulic Bending Systems

Hydraulic bending systems operate using fluid pressure, allowing higher force and controlled bending. They are capable of processing thicker materials and executing precise bends consistently. Hydraulic systems are widely used in industrial applications requiring medium to large-scale production and higher accuracy.

CNC Bending Systems

CNC (computer numerical control) bending machines represent the most advanced form of bending technology. Operators can program exact bend sequences, angles, and positions, ensuring consistent results even for complex shapes. CNC systems, also referred to as types of press brakes, are ideal for high-volume production, prototypes, and parts requiring repeatability. They reduce human error and enhance overall operational efficiency.

Electric and Hybrid Systems

Fully electric bending systems offer energy efficiency, minimal maintenance, and precise motion control. Hybrid machines combine electric and hydraulic features to provide both speed and power. These systems are versatile, supporting a wide range of materials and bend complexities.

Material Considerations in Bending

The type and thickness of metal influence machine selection. Common materials include mild steel, stainless steel, aluminum, and alloys. Each material requires specific force, tooling, and machine settings to achieve accurate bends. Modern bending machines can accommodate multiple materials, making them suitable for diverse fabrication tasks.

Applications in Structural Fabrication

Structural components like beams, brackets, and frames require uniform bends to ensure load distribution and stability. Advanced bending systems allow manufacturers to maintain consistent quality and meet engineering specifications, which is vital for construction and infrastructure projects.

Automotive Industry Applications

The automotive sector depends on precise metal components such as frames, panels, and brackets. CNC and hydraulic systems provide the accuracy and repeatability needed for high-volume production. Reliable bending ensures vehicle safety and optimal assembly efficiency.

See also: Enhancing Pipeline Operations with Modern Techniques

Custom Fabrication and Prototyping

Custom fabrication often involves unique designs and limited production runs. Bending machines offer flexibility to adjust angles and sequences, accommodating bespoke designs. CNC machines are particularly useful for prototyping, allowing rapid setup and precise replication.

Efficiency and Productivity

Modern bending machines enhance productivity by reducing setup times, minimizing errors, and producing consistent parts. Automation and programmability reduce manual intervention, allowing operators to focus on monitoring and quality control rather than repetitive adjustments.

Safety in Bending Operations

Safety features in modern bending types of press brakes systems protect operators from injury. Emergency stops, guards, and controlled motion minimize accidents. Proper operator training ensures safe use while maintaining productivity.

Maintenance and Reliability

Routine maintenance is crucial for machine reliability. Lubrication, inspection, and timely replacement of worn components prevent breakdowns and extend operational lifespan. Reliable machines ensure uninterrupted production and consistent output quality.

Integration with Digital Manufacturing

Many modern bending systems integrate with digital platforms for programming, monitoring, and process optimization. Data-driven control helps reduce errors, streamline workflows, and support smart manufacturing practices.

Reducing Material Waste

Accurate bending reduces scrap and material waste. Machines that consistently produce correct parts lower operational costs and contribute to sustainable production practices.

Economic Benefits of Advanced Bending

Investing in modern bending systems provides long-term cost savings. Reduced rework, faster production cycles, and lower material waste improve profitability and provide a strong return on investment.

Future Trends in Bending Technology

The future of metal bending includes greater automation, energy-efficient systems, and smart manufacturing integration. Predictive maintenance and digital process control are increasingly important for reducing downtime and improving production accuracy.

Conclusion

Modern bending systems are essential for efficient, accurate, and safe metal fabrication. Mechanical, hydraulic, CNC, and hybrid machines each offer unique advantages, supporting applications from structural components to custom prototyping. Selecting the right machine and maintaining it properly ensures consistent quality, cost-effectiveness, and productivity.

By leveraging advanced bending solutions, manufacturers can meet evolving industrial demands while preparing for future technological advancements.