Efficient Organization for Metal Fabrication Workshops

Introduction

In metal fabrication, productivity and precision depend not only on machinery but also on how well equipment is organized and maintained. A well-arranged workshop minimizes downtime, enhances safety, and ensures consistent quality output. One critical aspect of this setup is the proper organization of bending tools. Effective management of these components, particularly through an optimized system for press brake tooling storage, can transform how operations are conducted on the shop floor.

Importance of Organized Workspaces

A cluttered or disorganized workspace leads to inefficiencies that can delay production and increase errors. When tools are scattered or misplaced, machine operators spend valuable time searching for the correct piece of equipment. This wasted time accumulates over multiple shifts, resulting in decreased productivity.

By creating an organized layout where every tool has a designated location, fabrication teams can reduce setup time, avoid tool damage, and maintain a clean working environment. This organization is especially crucial for facilities that handle various tool sizes, materials, and bending operations.

See also: How Technology Is Revolutionizing the Fitness Industry

Understanding the Need for Specialized Storage

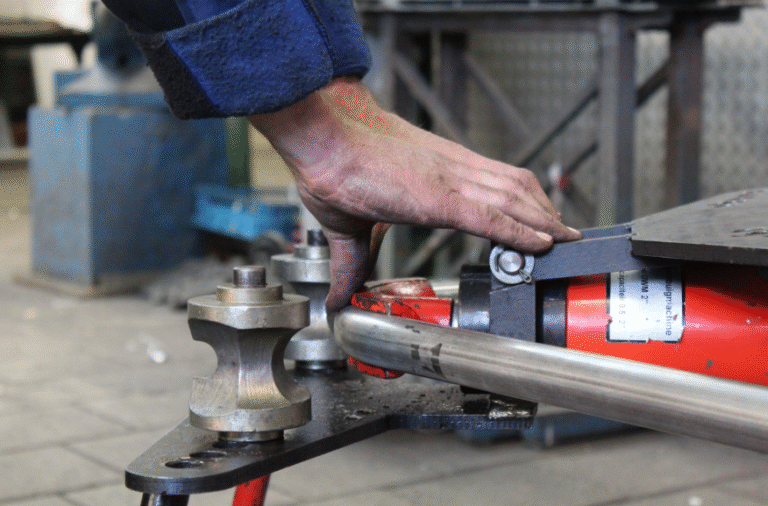

Bending tools are precision components used in forming sheet metal into desired shapes. These tools are often heavy, expensive, and require specific handling to avoid damage. Therefore, generic storage solutions like simple shelves or boxes are inadequate.

A dedicated system for press brake tooling storage allows for categorized placement of punches, dies, and adapters according to size, shape, or frequency of use. It also provides secure handling to prevent rust, chipping, or deformation of edges. This structured storage approach ensures long-term durability of tools and consistency in bending accuracy.

Types of Storage Systems

Tool Cabinets

Tool cabinets are one of the most efficient and space-saving methods of organizing bending tools. These cabinets feature adjustable drawers and dividers that can be customized according to the size and type of the tool. With clear labeling, operators can quickly locate the required item.

Tool Racks

Tool racks are ideal for workshops that require frequent tool changes. The open design allows for quick access and easy visibility. Heavy-duty racks made of steel or aluminum are preferred for their durability and ability to support large tool weights.

Mobile Storage Carts

For larger workshops where tools press brake tooling storage must be moved between machines, mobile carts offer flexibility. They are often equipped with lockable wheels and cushioned trays to protect tools during transport.

Wall-Mounted Holders

Wall-mounted systems are space-efficient options suitable for smaller workshops. They help keep the floor area clear and make commonly used tools easily accessible to operators.

Material and Design Considerations

The construction material of a storage system significantly influences its durability. Stainless steel or powder-coated steel is preferred due to its resistance to corrosion and wear. Foam or rubber inserts can be added to drawers to cushion the tools and prevent sliding or impact damage.

The design should prioritize both safety and convenience. Rounded corners, secure locks, and ergonomic height considerations ensure that tools are stored safely and accessed comfortably by operators.

Advantages of Proper Storage

Improved Efficiency

Organized tools mean less time wasted searching for components, allowing operators to focus on production. Faster tool changes directly lead to reduced machine downtime.

Enhanced Tool Life

Proper storage prevents tools from colliding or rubbing against each other, reducing surface wear and maintaining sharpness for a longer period.

Better Safety

By keeping tools off the floor and in designated storage, the risk of accidents and injuries is minimized. It also helps maintain a cleaner, safer work environment.

Cost Reduction

Well-maintained and properly stored tools require less frequent replacement, saving money over time. Additionally, improved workflow reduces labor costs and increases output.

Implementation in Modern Workshops

Many modern metal fabrication facilities are adopting lean manufacturing principles to eliminate waste and improve process flow. Implementing a structured press brake tooling storage system aligns perfectly with these goals.

Operators can label each storage area based on tool type or project requirement. Incorporating digital inventory tracking systems further enhances efficiency by allowing real-time monitoring of tool locations and conditions. Some advanced workshops also use barcode or RFID tagging to automate the tracking process.

Maintenance and Upkeep

Simply installing a storage system is not enough. Regular maintenance ensures the system remains effective. Cleaning the storage areas, lubricating metal surfaces, and inspecting for wear should be done routinely. Training operators to return tools to their designated spots after use is equally important.

Periodic audits can also help identify inefficiencies or areas where the organization can be improved. For example, tools frequently used together can be grouped in the same section for quicker access.

Future Trends in Tool Management

With the growing influence of Industry 4.0, digital management of tooling systems is gaining traction. Smart storage solutions integrated with workshop management software can monitor tool usage, predict wear, and schedule maintenance automatically.

This technological evolution not only improves productivity but also ensures better decision-making in production planning. The integration of automation and data analytics in tooling management is shaping the future of efficient metal fabrication operations.

Conclusion

Efficient organization within a metal fabrication workshop is vital for achieving precision, safety, and productivity. An effective system for press brake tooling storage helps prevent tool damage, reduces downtime, and optimizes workflow. By investing in proper storage infrastructure and adopting modern management practices, manufacturers can ensure consistent production quality while extending the life of their valuable tools.

Ultimately, thoughtful organization and maintenance of these essential tools create a foundation for a smoother, more profitable, and safer manufacturing process.